What is a good tile edging strip?

Definition of Tile Edgebanding

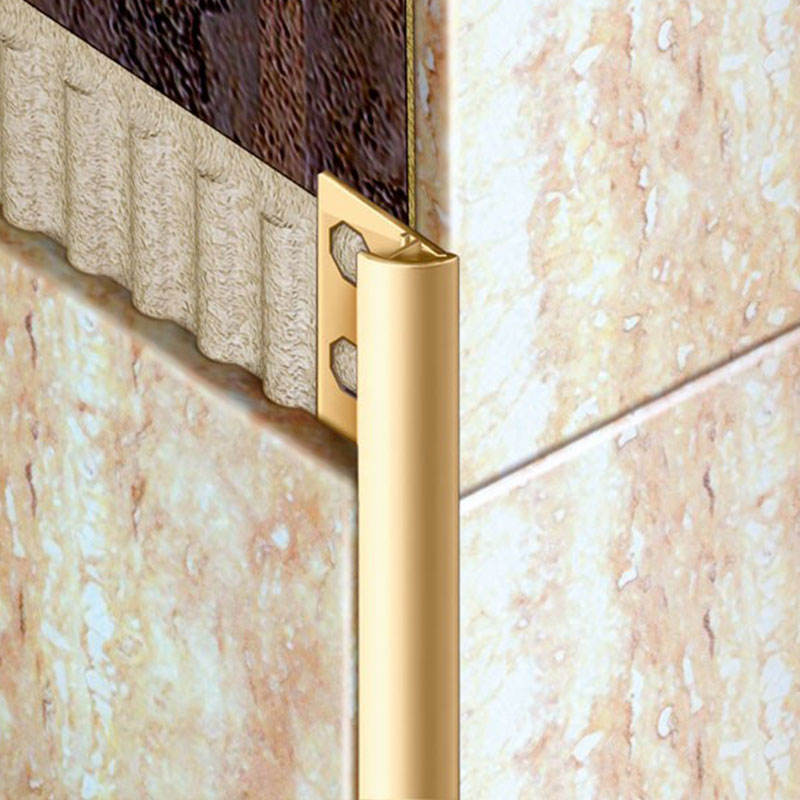

Tile Trim, also known as Tile Edge, is a profile specially designed to protect and decorate the edges of tiles after they have been laid. It is usually installed in the tiles and walls, window sills, countertops or the junction between different materials on the ground, to play the role of closing, landscaping, anti-bumping, waterproof and moistureproof and to avoid the tiles due to uneven stress and cracking. High-quality edge strips can not only fit perfectly with the tiles to form a smooth transition, but also in the line of sight to achieve the decorative effect of the finishing touch. It is a functional component in the overall space, but also a decorative line, through the material, color and shape of the diversity, can seamlessly fit with the texture of the tiles, so that the edge of the wall or the ground more delicate. When choosing, you need to take into account the wear resistance, corrosion resistance, waterproof, collision resistance and other performance indicators to ensure that in the kitchen, bathroom or outdoor and other environments can be maintained for a long time beautiful and intact.

The basic components of tile edging strips

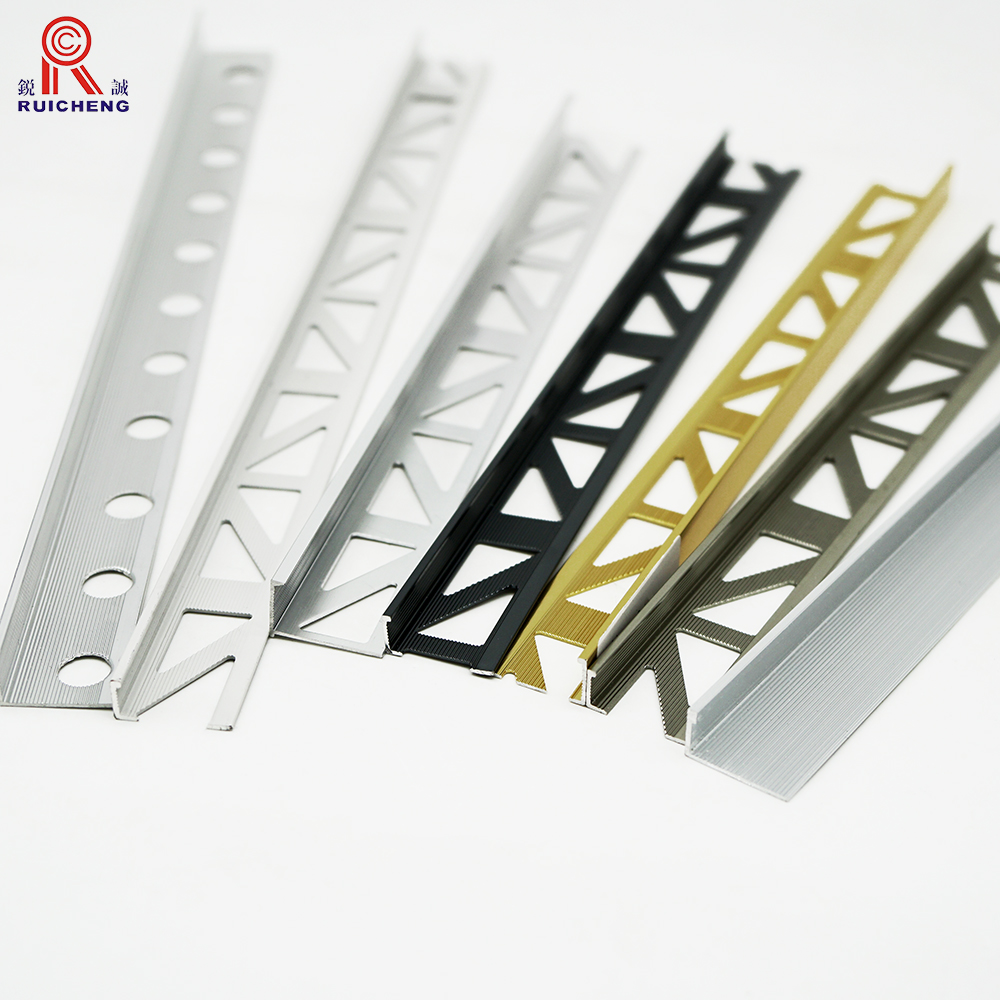

Tile edging strip usually consists of three parts: substrate, surface decoration layer and installation slot. The base material is the skeleton of the profile, which determines its strength and stability; the surface decoration layer has a direct impact on the beauty, wear resistance and corrosion resistance; the design of the installation slot relates to the late construction efficiency and stability.

- Substrate:common aluminum alloy, plastic (PVC, ABS), stainless steel, etc., of which aluminum alloy is widely used for its light weight, high strength, rust resistance and recyclability, and it can still maintain its shape after carrying tile crimps.

- Surface coating:anodic oxidation, electrophoretic spraying, powder coating, wood grain transfer or imitation stone texture and other processes are optional, not only to make the profiles colorful, but also to ensure scratch-resistant and not easy to fade

- Mounting Slot:Card slot can be divided into open type and concealed type, open card strip exposed aesthetics, concealed card slot needs to be installed together with the tile reserved gap, the overall smoother. High-quality slot design to ensure that the edge of the strip and tiles, wall close fit, not loose, not warped, while facilitating late maintenance or replacement.

Material description

The selection of materials for tile edging strips determines their physical properties and service life. Mainstream materials include:

- Aluminum alloy profile:6063 or 6061 series aluminum is usually used, which has the advantages of light weight, high strength, not easy to deform, and never rust; the surface of the substrate can be anodized to form a dense oxidized film, which enhances the corrosion resistance, or electrophoretic spraying or powder coating to obtain a variety of colors and textures; the aluminum material can be recycled 100%, which can be used in a sustainable way.

- Plastic profiles (PVC/ABS):waterproof, corrosion-resistant, low-cost features, can be laminated or baked paint to achieve wood grain, stone grain or metal texture, but the relative abrasion resistance, impact resistance is slightly inferior, need to be decided according to the environment.

- Stainless steel profiles:common 304/316 stainless steel, high hardness, high temperature resistance, corrosion resistance, commonly used in commercial or outdoor scenes, but the cost is higher, processing difficulty.

- Artificial stone or natural stone:Used in high-end space, luxurious texture, but heavy weight, high installation difficulty, and significant increase in cost.According to the use of the scene (kitchen and bathroom, balcony, indoor floor, etc.), budget and aesthetic needs, a reasonable choice of materials, in order to balance the functionality and visual effect.

Therefore, aluminum alloy profile flooring will probably be the best choice for you

Comparison of Product Differences

Even if the same aluminum alloy edge strips, there are still significant differences between different brands and models:

- Alloy Composition:6063 is commonly used for general decoration and has strong oxidation resistance; 6061 has higher strength but slightly higher processing cost; the ratio of different alloying elements affects the hardness and processability.

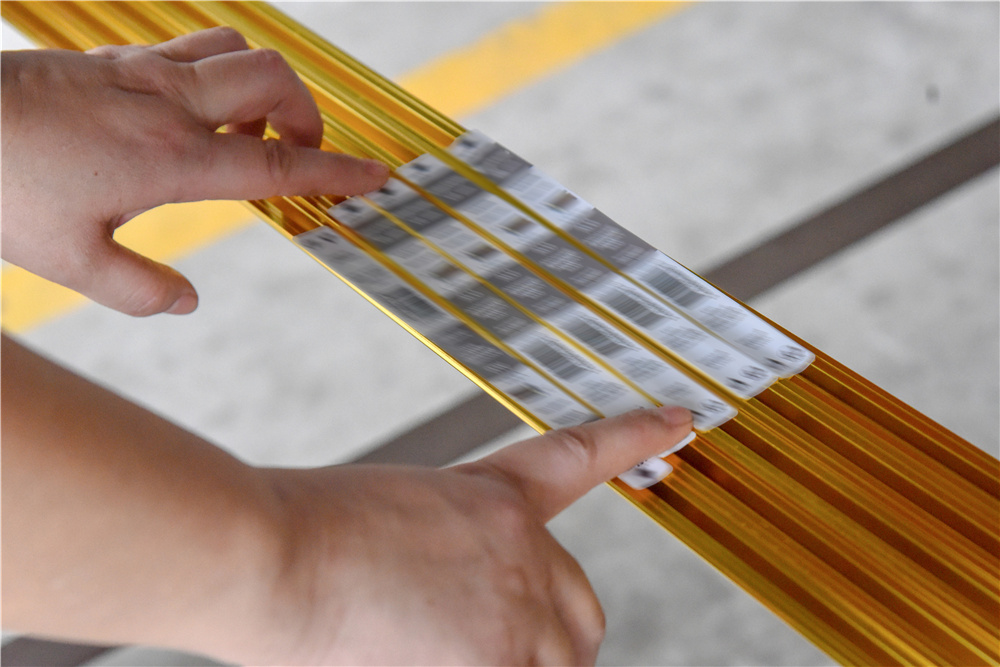

- Extrusion process: High-precision extrusion equipment can control the cross-section tolerance within ±1 millimeters to ensure that the edge strip and the tile gap close to reduce the hollow drum or warped edges.

- surface treatment process: anodic oxide film thickness, spray coating adhesion, wood grain transfer clarity, environmental protection level and other indicators to determine the beauty and durability; high-quality brands often provide a number of international environmental protection certification.

- Complete degree of accessories:including internal and external curved parts, right-angled parts, over the door parts, tee parts and end caps, etc., the richer the variety of accessories, the smaller the splicing gaps in the construction process, the overall visual leveling.

- After-sales service: Provide on-site measurement, sample trial installation, installation training and warranty period support, which can effectively reduce the construction risk and later maintenance costs.

Product Benefits

Aluminum tile edging strips offer multiple advantages on both a functional and decorative level:

- Strong durability:Aluminum alloy itself has excellent tensile strength and bending resistance, and is not easy to be deformed or cracked due to daily bumping.

- Waterproof and Moisture Resistant:Aluminum does not absorb water and does not breed mold, so it can remain intact for a long time even in high humidity environments such as kitchens and bathrooms.

- Environmentally friendly and recyclable:aluminum can be recycled an unlimited number of times, in line with the concept of green building and sustainable development.

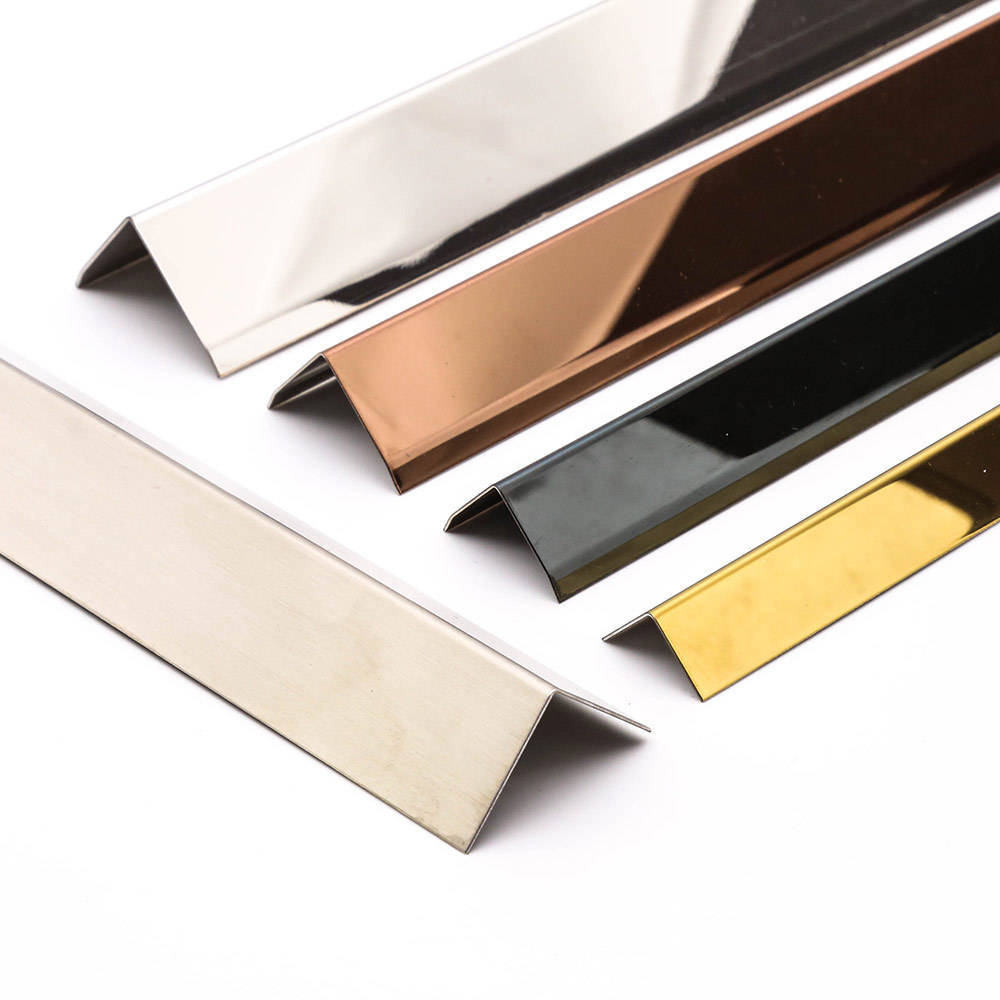

- Diversified Decoration: The surface can realize rich effects such as mirror, brushed, imitation wood grain, imitation stone grain, etc., which can be seamlessly matched with various tile styles.

- Convenient construction:the supporting slot and accessories are perfect, realizing quick snap or paste installation, reducing the construction cycle and ensuring the aesthetics.

- Excellent weather resistance:under direct sunlight or outdoor environment, the fluorocarbon sprayed aluminum alloy can still keep the color stable, without fading or chalking.

Aluminum tile edge strips have multiple significant advantages that can add value to the space in terms of protection, decoration and maintenance. First of all, high strength and high rigidity is the basic guarantee of aluminum alloy edge strip. High-quality 6063 or 6061 aluminum alloy substrate, its tensile strength of up to 150-200 MPa, bending strength is also very considerable, in the daily movement of furniture or cleaning operations will not produce almost no dent or deformation. Secondly, the excellent corrosion and moisture resistance makes it possible to keep it intact for a long time in a humid environment. After anodic oxidation or electrophoretic spraying on the surface of aluminum alloy, the thickness of the oxide film or coating can reach 10-20 μm, which can not only resist the long-term erosion of water vapor, detergents and chemicals, but also prevent mildew and bacteria, which can significantly prolong the service life of the wall and tile edges. Again, diversified surface decorative effects to meet the needs of all types of decorative styles - from the metal color, brushed effect, to wood grain transfer, imitation stone texture, to fluorocarbon spraying of bright colors, through technological processes to achieve ultra-high simulation and uniformity, whether it's a modern minimalist, Scandinavian style, or European classical, can be perfectly integrated with the texture of the ceramic tile. Fusion. Furthermore, environmental protection and recyclability is another major advantage of aluminum alloy. Aluminum itself can be 100% recycled, in line with the concept of green building and circular economy, the production and disposal process can significantly reduce the waste of resources. In addition, easy installation and simple maintenance also make it popular in engineering projects. The perfect slot, special fasteners, adhesive backing and screw base installation program make the edge strip can be quickly “stuck” into the reserved gap, without the need for a large number of secondary cuts; later if you need to replace a single profile, you can also be in the overall layout of the situation does not affect the local dismantling. Finally, weathering and anti-aging performance after fluorocarbon spraying or high-quality powder coating of aluminum alloy edge strip, UV resistance can exceed 5000 hours, will not fade, chalking or brittle due to direct sunlight, temperature changes or air oxidation, suitable for indoor and outdoor occasions. Taken together, aluminum alloy tile edging strips excel in strength, durability, aesthetics, environmental friendliness and ease of maintenance, making them an indispensable and high-quality edging material for modern homes and commercial spaces.

Types of Tile Edge Strips

According to different dimensions, the edgebanding can be divided into the following categories: material classification, modeling classification, surface technology classification, installation method classification, functional classification and style classification, a total of six dimensions, to help users quickly locate the most suitable products according to the project requirements.

Material Type

- Aluminum alloy:lightweight and high strength, rust and moisture resistant, recyclable.

- Plastic (PVC/ABS):low cost, texture can be customized, but the relative abrasion resistance and impact resistance is slightly inferior

- Stainless steel:high hardness, high temperature resistance, corrosion resistance, suitable for commercial and outdoor, but high cost, processing difficulty.

- stone/artificial stone:luxurious texture, wear-resistant and weather-resistant, but heavy weight and high cost.

Each material has its own emphasis on physical properties, price and aesthetics, which should be weighed against the installation environment and budget. The core of the tile edge strip lies in the choice of substrate, different materials in the performance, cost and application scenarios. Aluminum alloy is the mainstream choice, commonly used 6063 and 6061 series: 6063 aluminum profiles have good plasticity and oxidation resistance, can be formed by extrusion and electrophoresis or anodic oxidation on the surface; 6061 aluminum profiles have higher tensile strength and superior impact resistance, but the processing cost is slightly higher. Aluminum alloy edgebanding combines light weight, high strength, waterproof, no rust, and 100% recyclable, which is the first choice for high-end projects and green buildings.

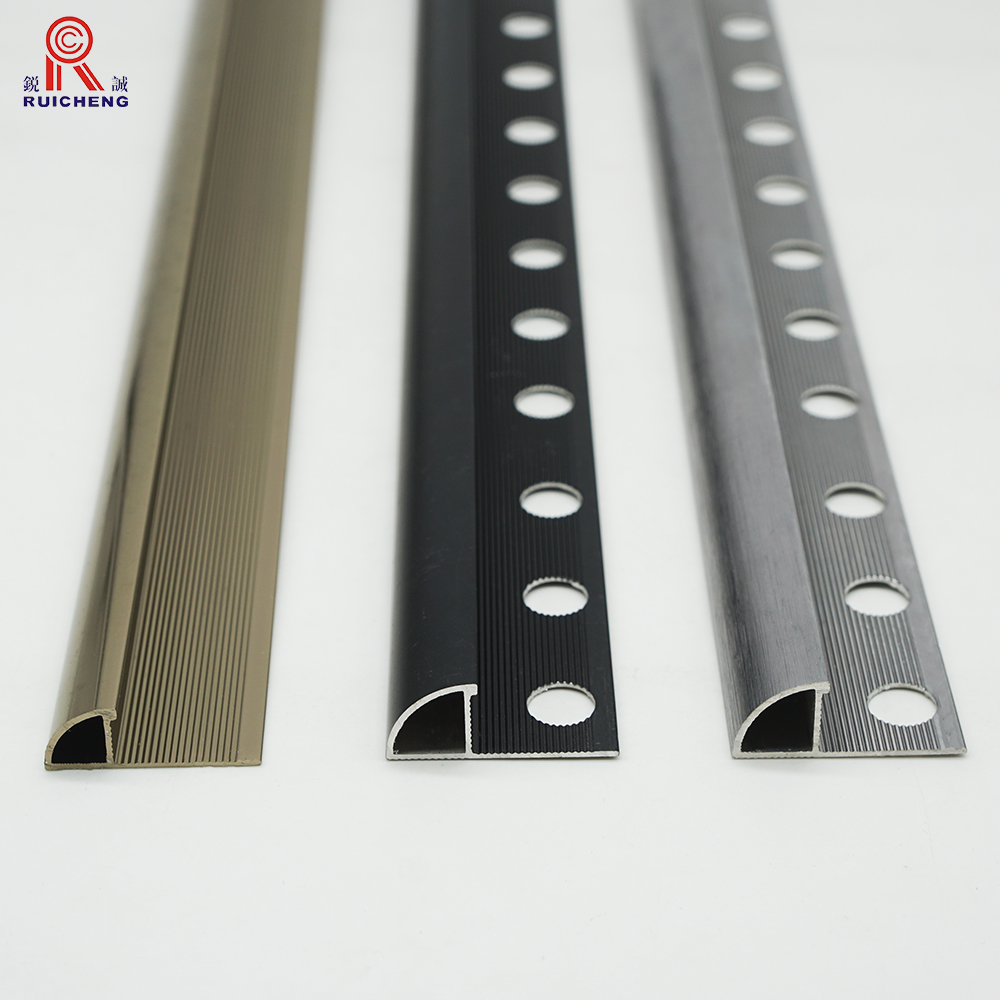

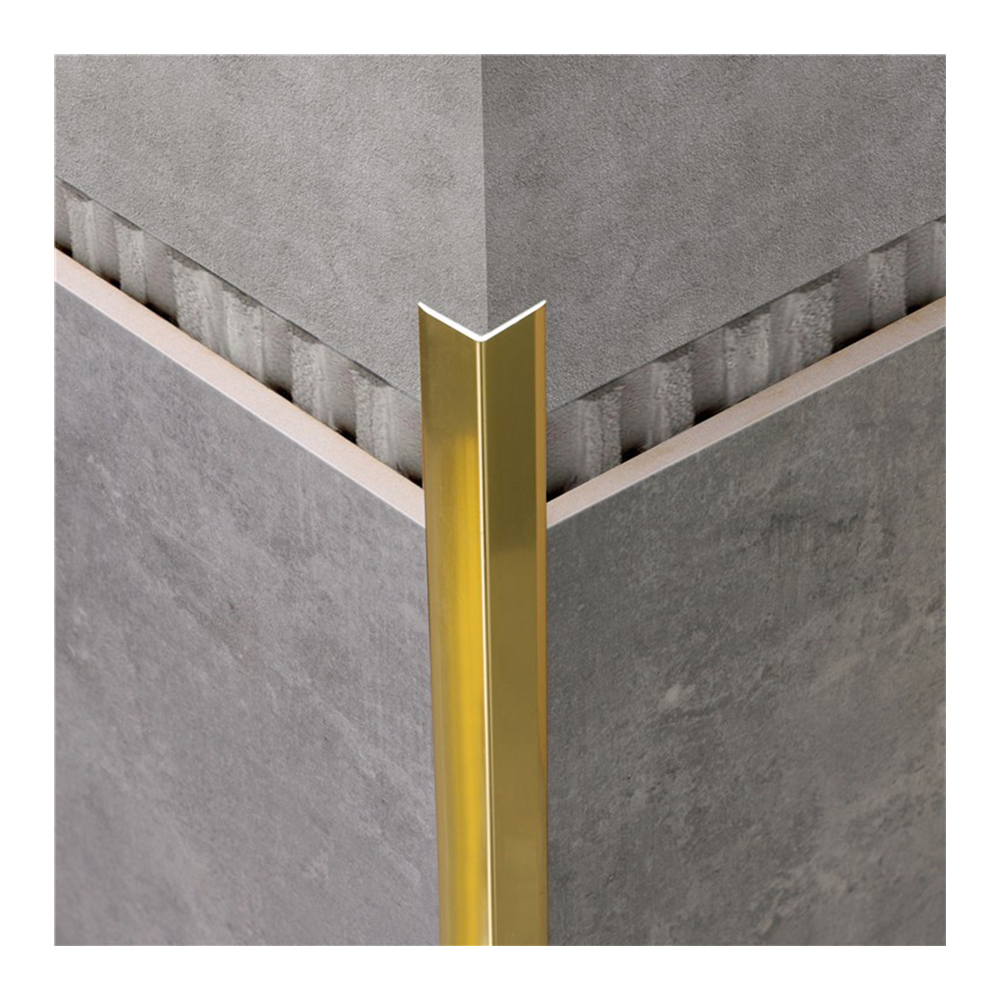

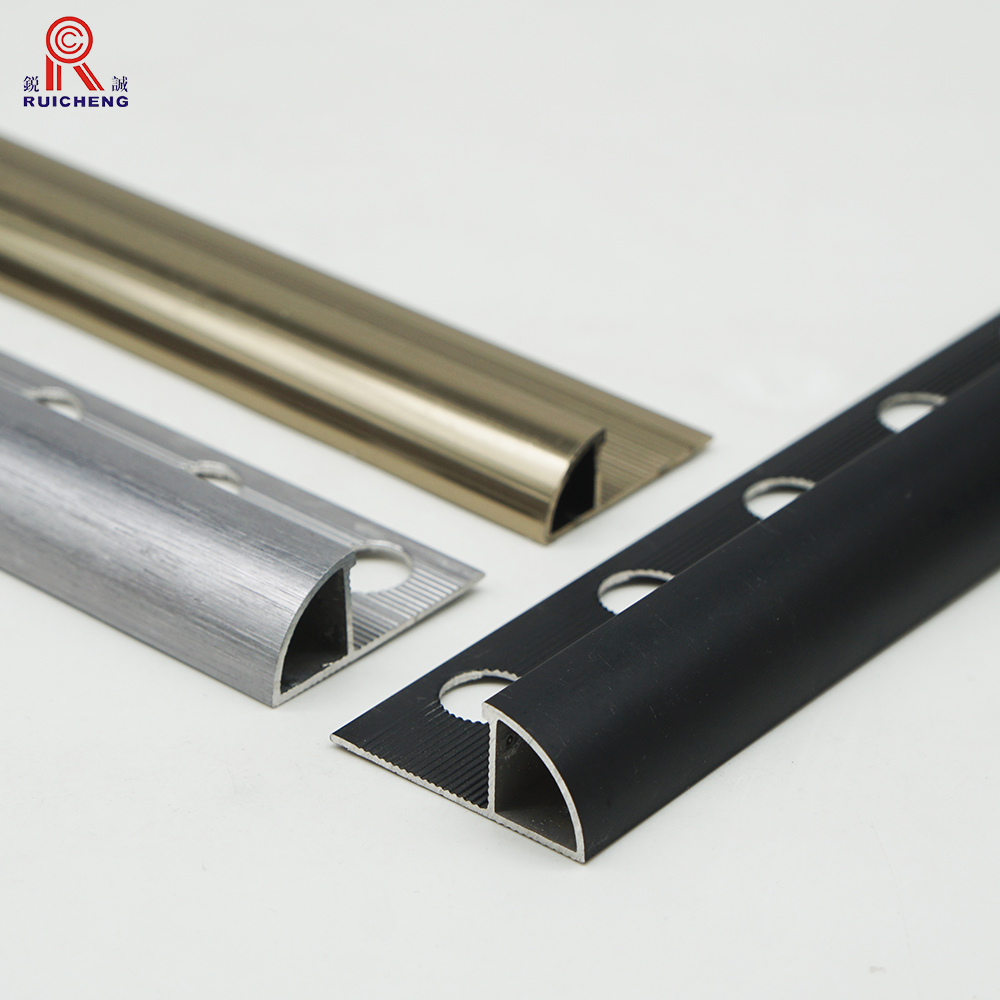

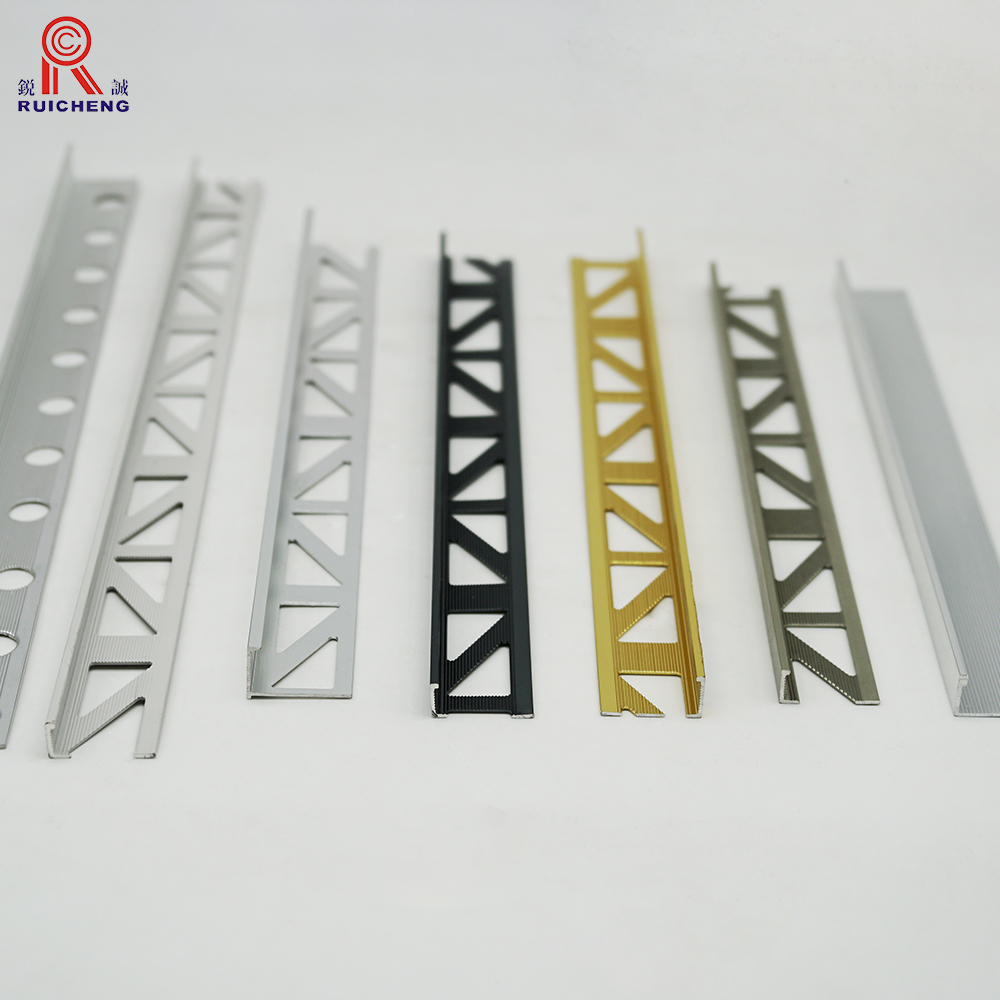

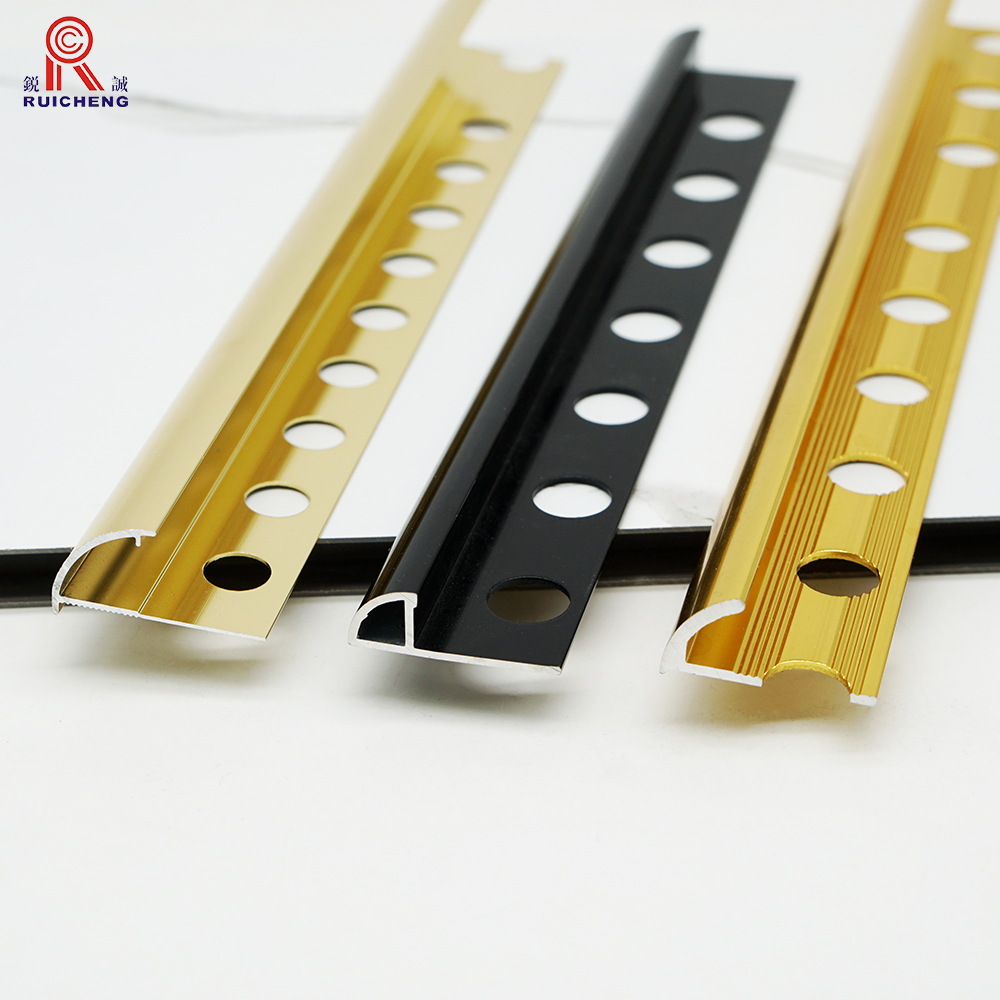

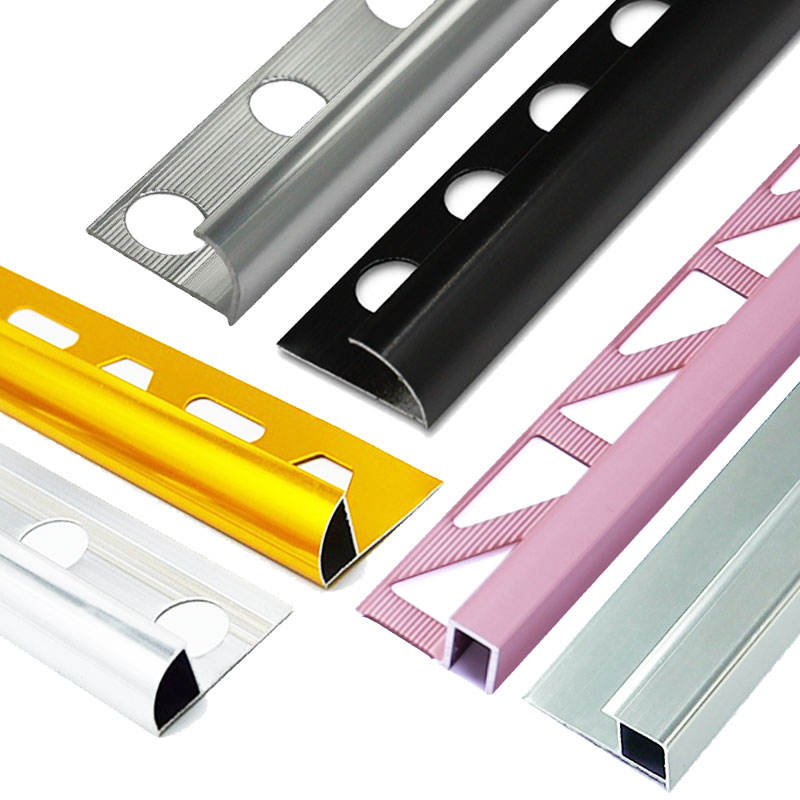

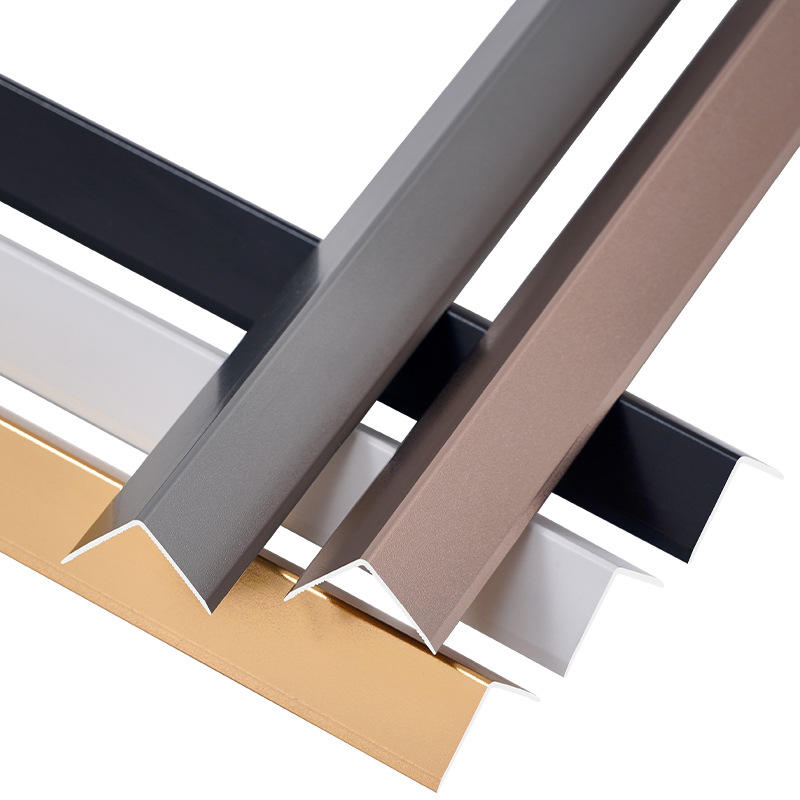

Modeling Type

- L Shape:the most common L-shaped cross-section, suitable for general wall or floor corner edging.

- Round shape: the edge of the arc transition is soft, commonly used in the bathroom or require a rounded edge of the scene.

- Ladder Shape:multi-layer ladder section, enhance the visual level, suitable for modern minimalist or European style.

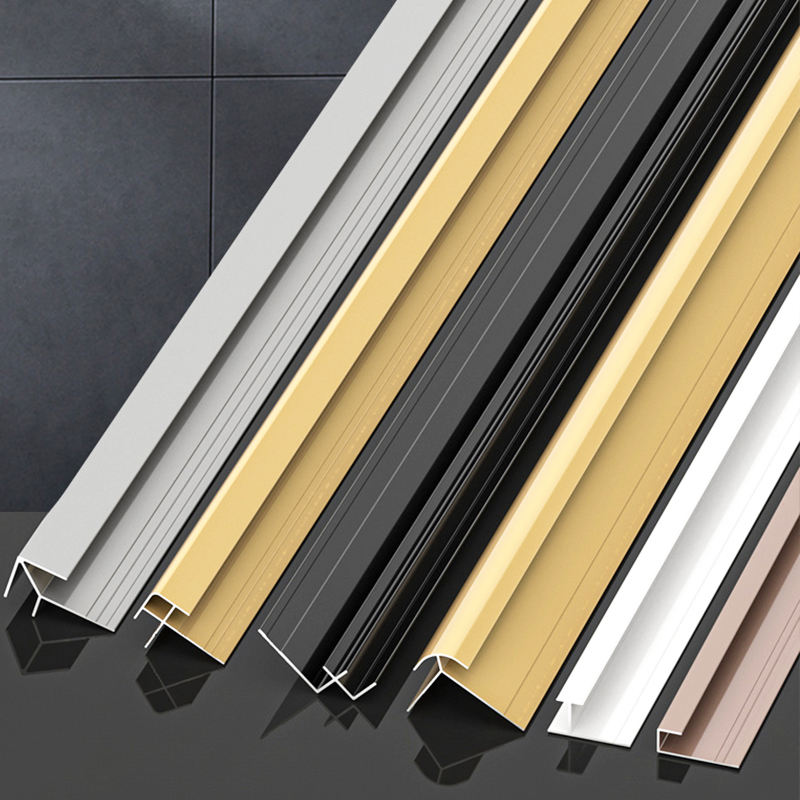

- T-type/U-type: used for splicing of different materials on the ground, horizontal or vertical splicing treatment.

- Customized shaped: to meet the needs of special shapes or patterns, personalized cross-section through CNC machining.

The cross-section modeling of the edge strip directly determines the visual effect and functionality after paving. Right-angle L-type is the most common basic modeling, sharp edges, dry lines, mostly used for wall-ground junction of the standard closure; curved type through the transition of rounded corners, suitable for bathrooms, kitchens and other places that require a sense of security and softness, can reduce the damage of the bump; ladder type cross-section will be divided into two to three steps, visually enhance the sense of hierarchy, commonly used in modern minimalist or new Chinese design; T-type and U-type are mainly used for tiles and tiles with other floor materials (wood flooring, carpets), smooth transition between different materials splicing functional closure. T-type and U-type are mainly used for smooth transition between tiles and tiles, tiles and other floor materials (such as wood flooring, carpets), to achieve functional edging of different materials splicing; special shaped customization to meet the needs of personalized or complex environments, through the CNC processing or mold customization to achieve a unique cross-section profile, such as hollow patterns, decorative lines. When choosing the shape, not only to consider the aesthetics, but also need to be combined with the actual construction error, tile thickness and caulking width, to ensure that the edge of the edge strip and tile edges close to the tight fit, no overhangs, no gaps.

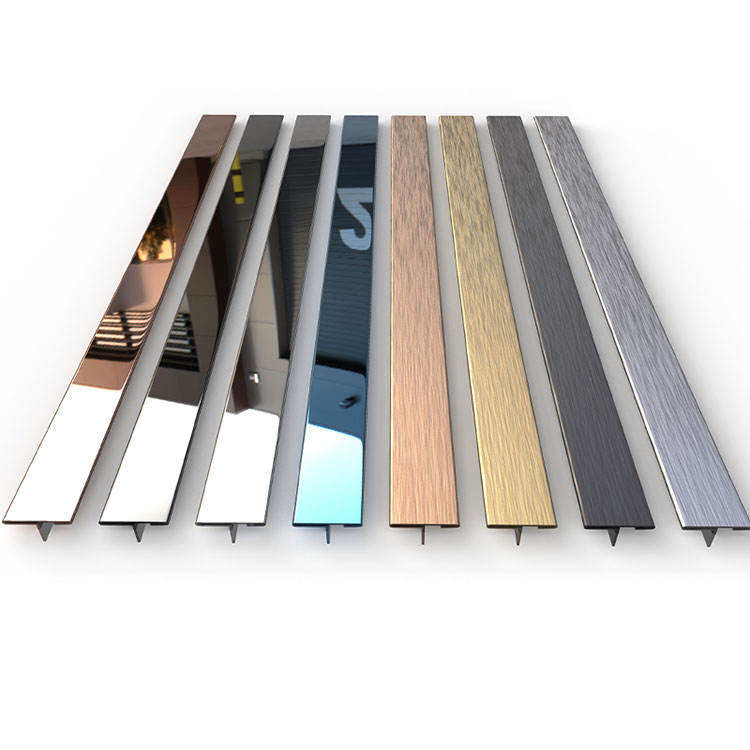

Type of surface treatment process

- Anodizing:Formation of hard oxide film, enhanced corrosion and wear resistance.

- Electrophoretic spraying:uniform and dense coating, strong adhesion, smooth surface.

- Powder Coating:Environmentally friendly and non-polluting, with excellent weather resistance.

- Wood grain transfer:Realize high simulation wood texture on metal surface.

- Fluorocarbon spraying: optimal UV and oxygen aging resistance, suitable for outdoor use.

Surface technology determines the color performance, abrasion resistance and aging resistance of the edgeband. Anodic oxidation is to generate an oxide film on the surface of aluminum, the thickness of the film layer can be adjusted (usually 10-20 μm), with excellent corrosion and abrasion resistance, and can maintain the natural luster of the metal color. Electrophoretic spraying adopts electrochemical principles, so that the coating is uniformly adhered to, the coating thickness is uniform, the adhesion is very strong, anti-peeling; powder spraying is characterized by environmental protection and solvent-free, after curing, the coating is dense, better weathering resistance, commonly used in outdoor or semi-outdoor places. Wood grain transfer can be realized in the metal surface high simulation of wood grain texture, combined with wear-resistant transparent protective layer, not only to enhance the natural texture, but also eliminates the hidden danger of deformation of solid wood; fluorocarbon spraying ultraviolet, oxidation, aging resistance performance is optimal, usually used in outdoor corridors, balconies, and other long-term sunshine area. When choosing the process, we should focus on the coating thickness, environmental protection level (such as RoHS, REACH and other standards), the number of scrub resistance and salt spray test indicators to ensure the long-term use of the effect.

Function Type

- waterproof and moisture-proof type: with drainage groove or sealing strip at the bottom, suitable for kitchen and bathroom and other humid environment.

- Anti-collision and anti-knock type:adding elastic cushioning material to the surface or bottom to reduce impact damage.

- Concealed wiring type:internal reserved wire slots, can hide weak power, network cable, beautiful and practical.

- Fire-retardant and flame-retardant type:adopting flame-retardant materials or flame-retardant treatment to meet the requirements of fire code.

According to the additional functions, the edge strips can also be divided into a variety of specialized types. Waterproof and moisture-proof type with drainage groove or sealing strip design at the bottom to prevent water from seeping into the grass-roots level along the foot of the wall, suitable for kitchen and bathroom, pool edge and other high humidity environment; impact buffer type in the surface or the back of the increase in the flexible rubber or EVA foam material, can effectively absorb the impact energy to reduce the personnel bump or furniture collision brought about by the damage, more used in hospitals, schools, nursing homes and other public places; hidden cabling profiles inside the reserve Wire or network cable slots are reserved inside the profile, which can hide the weak electricity and security cables without affecting the aesthetics, and are commonly used in smart homes or office spaces; fire-retardant profiles are made of flame-retardant materials with B1 level or higher standards, and with blocking adhesive or sealing strips, which can satisfy the fire safety norms of high-rise buildings or public buildings; antibacterial and hygienic profiles are made of antimicrobial agents added to the base material or surface coating, which reduces the propagation of bacteria, and are suitable for the hygiene requirements of hospitals, food processing workshops and laboratories, and so on. It is suitable for hospitals, food processing workshops, laboratories and other environments with high hygiene requirements.

How to Choose the Best Aluminum Tile Edging Strip

When choosing aluminum alloy edge strips, the following eight dimensions should be evaluated comprehensively: material grade, thickness, surface technology, structural design, size ratios, color matching, accessory perfection, as well as brand and service.

Aluminum Grade

Commonly used 6063, 6061, 6060 and other series. 6063 is cost-effective because it combines strength and workability; 6061 is stronger and has excellent impact resistance; and 6060 is economical and practical. According to the project pressure, wear resistance requirements and budget, reasonable selection of aluminum grade, to ensure both durable and economical.

thicknesses

Aluminum edgebanding thicknesses usually range from 1.0 to 3.0 mm. 1.0 to 1.2 mm is lightweight and low-cost, suitable for light loads or indoor dry areas; 1.5 to 2.0 mm is a common thickness, balancing strength and cost; 2.5 to 3.0 mm and above are suitable for high-frequency use in public corridors, shopping malls, and other scenarios. Thickness selection should be based on collision risk and frequency of use.

Surface Process

Preferred anodic oxidation film thickness ≥ 10μm, electrophoresis or powder coating in line with international environmental standards, wood grain transfer texture clear and natural, fluorocarbon spraying UV resistance ≥ 5000 hours. Surface technology directly determines the aesthetics and weather resistance, should be combined with the space function and maintenance frequency to choose.

structural design

Reasonable depth and width of the slot, tolerance control within ± 0.2 mm, snap torque is moderate, the fittings are tightly and seamlessly connected, and sufficient space is reserved for the wire groove, all of which are related to the convenience of installation and later maintenance. Well-designed edgebanding can realize the construction experience of “quick installation, flatness and no loosening”.

sizes

The height is 8mm, 10mm, 12mm, 15mm, etc., which should be matched with the thickness of tiles and caulking width; the length is usually 2.5m, 3.0m or customized to reduce the seams; the width should be chosen flexibly according to the hemming scenarios (walls, floors, countertops). The scientific size ratio can ensure the construction with less joints and high aesthetics.

colors

It is appropriate to tile color and decoration style with the same color or contrast with: dark tiles with the same color or differential metal color, enhance the sense of layered; light-colored tiles can be selected pure white, wood grain or metal bright colors to enhance the brightness of the space; commercial premises can be considered to brushed or mirrored effect, highlighting the sense of quality.

Accessories

Pay attention to the completeness and precision of fittings such as internal and external elbows, right-angled parts, tees, over-door parts and end caps. High-quality fittings can realize multi-directional splicing without gaps, ensure the overall line is smooth and consistent, and reduce secondary processing and on-site cutting due to the lack of fittings.

Brands & Services

Choosing a well-known brand in the industry, you can enjoy perfect quality inspection report, professional project measurement, sample trial installation, installation training and timely after-sales support. Brand reputation and the number of cases are the key to measuring reliability. Quality brands can provide technical guidance during the whole construction process, reducing risk and improving efficiency.

Recommended products

Based on the above multi-dimensional evaluation, we recommend the following cost-effective aluminum tile edging strips:

- Trim-A6063 Natural Silver:6063 aluminum alloy, 2.0 mm thickness, anodized natural color, suitable for modern minimalist and industrial style space, complete with accessories.

- Trim-B6061 Wood grain:6061 aluminum alloy, 1.8 mm thickness, high-definition wood grain transfer printing, warm texture, suitable for Scandinavian and new Chinese style decoration.

- Trim-C6063 Fluorocarbon Gray: 6063 aluminum alloy, 2.5 mm thickness, fluorocarbon spray surface, UV resistance, excellent weather resistance, suitable for outdoor balcony or shopping mall.

Trim-D6060 Mirror Silver: 6060 aluminum alloy, 1.5 mm thickness, brushed mirror finish, luxury texture, suitable for hotel lobbies and high-end residential.

All of the above products provide customized specifications, a full set of accessories and professional installation guidance, which can be flexibly selected according to the project requirements, to meet the requirements of different environments for edging and decoration.